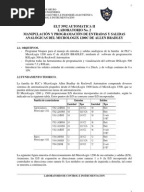

Pid Rslogix Manual

Basic PID Loop Programming in RSLogix 5000 / Studio 5000. The implementation of a PID control loop on a Programmable Logic Controller is simplified in many instances through dedicated instructions. The PID Instruction within an RSLogix based PLC allows the user to implement the mathematical functions of a PID loop without the extensive. PID Tuning Guide A Best-Practices Approach to Understanding and Tuning PID Controllers First Edition. The PID controller is the most widely used technology in.

SoftwareUse from Rockwell Software® to configure your MicroLogix™ programmable controllers. MicroLogix Systems Building BlocksThe following pre-configured building blocks implement common control tasks as part of your machine design. These building blocks use the RSLogix™ software and are available by ordering the. Project igi 6 conflict global storm free full game download. Application-focused building blocks.

Pre-written control programs. Quick start guides. Sample wiring diagrams. Sample bill of materials. Sample panel layouts. Sample HMI screens with diagnosticsAdditional software products are available from. Configuration & Selection Tools.

Peugeot planet 2000 keygen download free. — Convert competitive catalog numbers to similar Allen-Bradley® products. — Select hardware and generate bills of materials for projects. — Build complete quotes and proposals.Other Resources. — Obtain a variety of downloads to accompany your MicroLogix™ controllers.

— Visit our online resource to find the procurement specifications for this product. — Visit our online resource for technical information, support chat and forums, software updates, and product safety advisories/notices.

Question :

How can I setup a basic working ControlLogix PID?Environment :

RSLogix5000 programming and PID tuningCaution

A ControlLogix PID is a fairly complex instruction which should not be used with any real world equipment unless:- The programmer understands how to setup the PID.

- At the very least, the equipment is in a safe state.

Answer

To get a basic start on PID, the following steps can generally be used:

- Add a PID instruction by entering the following:

- The PID control tag.

- The tag to be used as the PID input into the PV field.

- A tag for TIEBACK (used in operator manual control) into the TIEBACK field.

- A tag to use for the output into the CV field.

- The PID can be used in a Periodic Task.

- In this case, the rung should be unconditional

- The period of the task should be matched with the loop update time of the PID.

- The period used is typically at least 10 times faster than the Loop Process time

- If using a Continuous Task, the PID should be regulated with a Timer bit.

- Match the timer preset with the loop update time of the PID.

NOTE: If this is not done, then the calclulations of the PID will not be consistent. The contribution to the output due to integratal and derivative parts of the equation will be proportionately effected in relation to the scan time. This will cause inconsistent behavour from the PID if it is not regulated.

- Match the timer preset with the loop update time of the PID.

- Enter the PID Configuration screen, then enter appropriate information for:

- Gains

- Loop update time

- Control action

- Scaling ranges on the Scaling Tab

Example ACD File

Attached is an ACD file that shows a simple setup for a PID. In this example, the PID is set to run from a 1 second timer and all scaling is set 0 to 1000.An example of a PID and a PIDE running in a simulation can also be found in 449308 - Basic Simulation of PID and PIDE

References

For more detailed information on the ControlLogix PID, please see the ControlLogix General Instructions Manual.Sourece : http://rockwellautomation.custhelp.com/app/answers/detail/a_id/40236